- #CONTROLAIR FLOW ARDUINO HOW TO#

- #CONTROLAIR FLOW ARDUINO SERIAL#

- #CONTROLAIR FLOW ARDUINO FULL#

- #CONTROLAIR FLOW ARDUINO PRO#

- #CONTROLAIR FLOW ARDUINO PC#

Set the pot at half way and the valve would be opened half way.

#CONTROLAIR FLOW ARDUINO FULL#

Turn it all the way to the right and it is at full flow. turn the pot all the way to the left and it is at 0 flow. So to simplify, I would read a potentiometer and set the air flow to correspond. If your need does reduce to such pure non-reactive sequencing then things are a lot simpler if it doesn't, then the rest of the explanation here applies. The variable air flow is to be controlled by an arduino.

#CONTROLAIR FLOW ARDUINO PC#

Given that there are no realtime inputs to the calculations, their results can also be stored on an SD card for use months later with no PC connection at all. A 3d printer could be an example of this - the really complex calculations are done on a PC, then commands are drip-fed a bit in advance of need to a simpler executive traditionally running on a repackaged Arduino Mega, and that moves the motors with sub-millisecond pulse precision. You can use it to count flow and volume of liquids and gases (although the documentation focuses on applications using liquids) and can support multiple flow sensors at the same time. Mere sequencing is a far easier problem, as you can send the data a bit in advance of need and hold it in a buffer, so that communication latency doesn't delay operations. FlowMeter is an Arduino library that provides calibrated flow and volume measurement with flow sensors. One thing that is not clear however is if your system needs to react in real time, or merely to sequence with precise timing. Beyond that you are really out of the realm where this could be considered an Arduino question - trying for example to run a realtime scheduler on the Linux half of a Yun is really not related to "Arduino" at all. The architecturally cleanest solutions would be to find a way to fit your calculations on a fast single processor - in the realm of Arduino-style solutions perhaps one of the latest in the Teensy series. An embedded board with a decent processor and good direct I/O (Beaglebone, maybe the Linux side of a Yun or comparable) would be better, but be aware that multi-tasking operating systems like Linux or Windows are fundamentally in conflict with real-time performance - it takes very complex hacks to make that work, for example running a realtime scheduler directly on the hardware and having it run an ordinary operating system as a low priority task. With the increasing isolation of PC processors from external I/O by multiple layers of intermediate architecture on the chip and motherboard, you see very little realtime use of PCs today. True realtime systems put the processing and the actuation in tightly connected local circuitry. Ultimately, USB is meant to move a lot of data in a reasonable amount of time - it is not designed to move small messages promptly. If you could get a USB high speed solution that would reduce this as the polling interval is shorter, but there are few such solutions for simple microcontrollers.

#CONTROLAIR FLOW ARDUINO SERIAL#

Using a part with direct USB rather than then needing to go through a serial link from USB chip to processor could help limit what is added on top of that, but it will still be there. Check out the related items below for a compatible wall-wart power supply.Going over USB will add about a millisecond of jitter to your data in both the sensing and command directions. the Pulse Input Module (PIM) can monitor and record energy consumption from.

#CONTROLAIR FLOW ARDUINO HOW TO#

I have the pin layout of both the RS485 board and the controllers serial output, I just dont know how to actually connect them together. The controller uses RS485 so I have purchased this board to hopefully facilitate that.

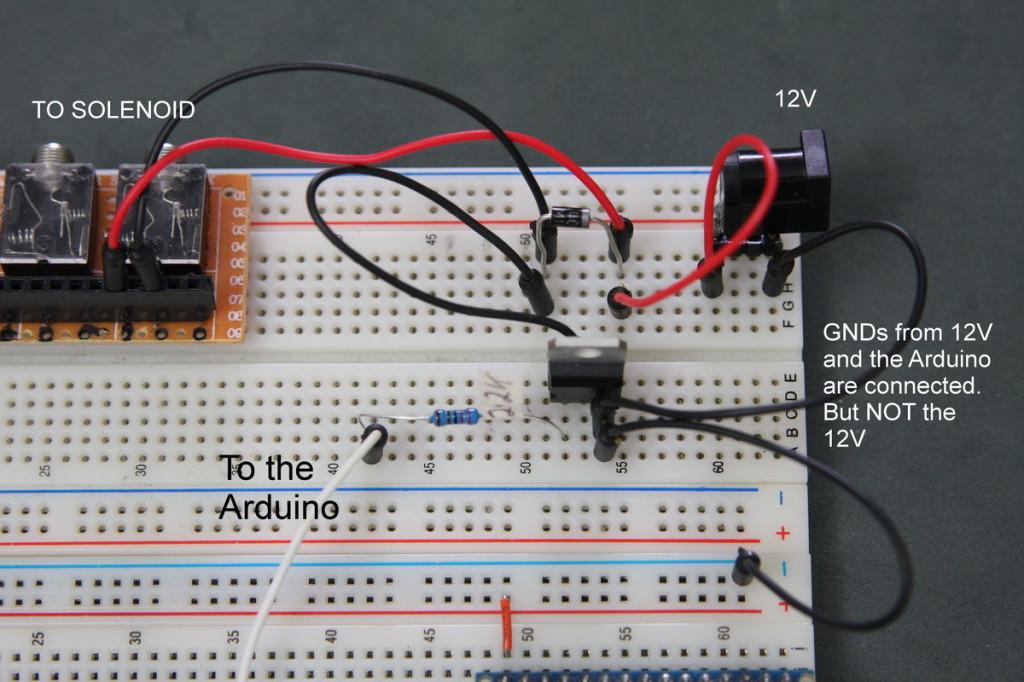

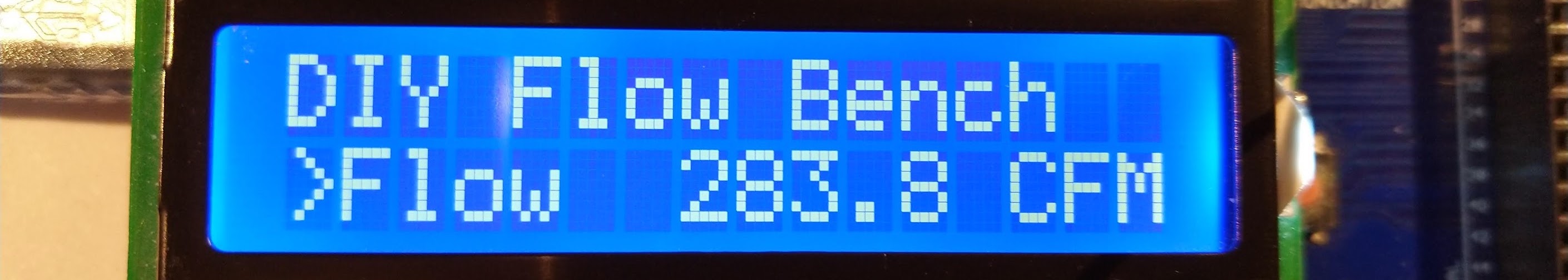

The on-board power regulator can handle anything from 7 to 15VDC. Replacement Universal Remote Control Air Conditioner for Samsung Brand. Hi there, So I am currently trying to control an air flow meter via an Arduino. You can power the RedBoard over USB or through the barrel jack. This version adds an SMD ISP header for use with shields. Note, the following libraries are needed: Wire. Make sure that the sensor's physical analogue pin matches up with the pin the software. We've also broken out the SDA, SCL and IOREF pins that showed up on the UNO R3, so the RedBoard will be compatible with future shields. Connect the pressure sensor up to your Arduino and connect the pressure taps to the ports of the pressure sensor. RedBoard has all of the hardware peripherals you know and love: 14 Digital I/O pins with 6 PWM pins, 6 Analog Inputs, UART, SPI and external interrupts. The RedBoard can be programmed over a USB Mini-B cable using the Arduino IDE: Just plug in the board, select "Arduino UNO" from the board menu and you're ready to upload code.

#CONTROLAIR FLOW ARDUINO PRO#

The SparkFun RedBoard combines the simplicity of the UNO's Optiboot bootloader (which is used in the Pro series), the stability of the FTDI (which we all missed after the Duemilanove was discontinued) and the R3 shield compatibility of the latest Arduino UNO R3. Each board is a bit different and no one board has everything we want, so we decided to make our own version that combines all our favorite features. At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one.

0 kommentar(er)

0 kommentar(er)